Food Processing

Don’t Fear an FDA or FSSAI “Swab-a-Thon”. Be Prepared with a Plan and Data

About The Invisible Enemy

Bacteria and viruses are stronger than ever. They travel faster, farther, and become increasingly resistant to antibiotics and traditional disinfection techniques. Much of what once worked to combat these dangerous microbes becomes less effective every passing day.

We protect Food Processors from harmful bacteria, Viruses and Fungi hiding in difficult-to-reach critical areas and in typical operating conditions, where standard methods often fail. If people are getting sick at your place of work, it threatens your productivity and your reputation. We can help you do something about that.

We Offer A Practical Solution

We give businesses and governments of all kinds access to the world’s most modern decontamination and infection prevention technologies. Treatments in your building target and kill the germs at the root of SBS. We build a shield for you that offers constant protection for you and your employees, and we do so in a way that is verifiable and affordable. We also provide emergency decontamination services to Food manufacturing units, hotels & restaurants on a nationwide basis.

Bacti Barrier disinfection and control programs include the following:

- Assessment and testing

- State of the art products and equipment

- Training and education

- Monitoring and certifications

Bacti Barrier Benefits

Kills 99.99% of Germs

24*7 protection

for 90 days

Suitable for

all surfaces

Monthly performance reports

Cost Effective

No need for daily sanitization

Monthly performance test

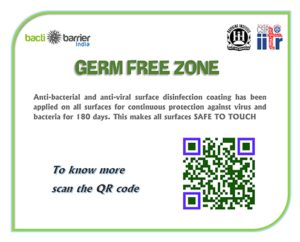

QR Coded certificate

Your Low-Risk Choice when You Require Results Everywhere, Every time

Food Processing

- Fresh, Prepared and Frozen Foods

- Ready to Eat Food Commissaries

- Pet Food Manufacturers

- High Risk Food Groups

Problem Areas

- Difficult to Clean Areas

- Presence of Organics & Water

- HVAC Systems & Ductwork

- Spiral Freezers

- Invisible Biofilm Formation

Harmful Contamination

- Aerosolized Pathogens

- Surface Transmitted Pathogens

- Accelerated Spoilage

- Changes in Composition

- Biofilm Reproduction

Regulatory Compliance

- FSMA

- FDA

- USDA-FSIS

- ORMI Organic Approval

- GMP/HACCP Validation

The Real World … Many high-risk food decontamination projects are performed on short notice with operational challenges that impede the ability of most technologies to destroy contamination everywhere. Cycle validation is not practical or cost-effective in these situations.

When you get one shot, and you better get it right.

This is where our ClorDiSys sterilization method shines. With flexible treatment parameters, performance is not compromised by hidden microscopic contamination, difficult-to-reach areas, equipment loading patterns, biofilms, light organic matter, residual water and temperature/humidity gradients.

Our Decontamination and Prevention Services Target:

- Bacterial Endospores

- Fungi & Mold

- Large Non-Enveloped Viruses

- Myco Bacteria

- Gram (-) Negative Bacteria

- Enveloped Viruses

- Small Non-Enveloped Viruses

- Gram (+) Positive Bacteria

- Beta Lactums & Pinworms

Bacti Barrier Service Process

STEP I - Assessment Of Contamination Through ATP/Swab Technology

This process gives us intelligence about the level of contamination present in the facility and the level of treatment required. In ATP Testing, we read the presence of Adenosine Tri Phosphate on a surface found in all microbial cells. The higher the ATP reading, the greater the threat.

STEP II– Applying Bacti Barrier Antimicrobial Surface Protector

Bacti Barrier Antimicrobial Surface Protector provides a bonded, long-term-antimicrobial protective barrier everywhere in the facility. We use electrostatic spray machines that are safe to spray antimicrobial chemicals on high-end electronic gadgets, expensive leather, or other fabric surfaces. It also ensures that every surface is coated evenly and fairly from all sides.

STEP III – Periodic Assessment For The Treated Facility

We conduct periodic assessments of all high touch surfaces to ensure no microbial growth in the treated facility. We use the same technology for assessment as mentioned in STEP 1. In case the reading is found to be higher than the acceptable limit during any of the periodic assessments, Bacti Barrier re-treats the facility without any commercial obligation to the client.

STEP IV: QR Code Stickers & Certificate

Display of QR coded treatment certificate at all touch points.